got know idea what I am doing!

4 posters

Page 1 of 2

Page 1 of 2 • 1, 2

god's money- Contributor

- Number of posts : 52

Registration date : 2019-08-13

Re: got know idea what I am doing!

Re: got know idea what I am doing!

GM,

You're going to have some fun with that gold wheel. Keep the photos coming as you progress.

You're going to have some fun with that gold wheel. Keep the photos coming as you progress.

Re: got know idea what I am doing!

Re: got know idea what I am doing!

Mmmmm ,well i'll give you 10/10 for the welding , ( nice welding bench too ) But yeah I think your wasting your time ,it won't work any near as effectively as a moulded plastic one , ( 1) those beads of weld are only going to impede the water / material flow ( 2 ) the rust factor ( 3 ) the weight factor after finishing it ,( wouldn't like to be carrying it any distance ) ( 4 ) the difficulty of mounting a magnet on it ( trying to extract any magnetic material )

I've only used one 2-3 times ? ? , ( used a mates one , under his supervision ) and he was preety pendantic in it's use ,and mostly uses it for concentrates , ( with some other material mixed in ) he stressed in the setting up of it ,ie ; the angle of it and the water flow of it ,were most important ,plus he used to use detergent in his recirculate water in order to soften the water up a bit , also allowing the plastic surface to become as smooth / shiny / slippery so as to allow water / material flow .Spiral Wheels are great bits of gear ,slow admittedly ,but great for concentrates ,and trying to extract magnetic black sands ,but only when used properly .Others might disagree ,but any way that's my opinion .

hugh62- Contributor Plus

- Number of posts : 363

Age : 62

Registration date : 2014-02-09

Re: got know idea what I am doing!

Re: got know idea what I am doing!

Hugh,

Do agree about the weight factor, probably an over kill with the welding, but water/material flow won't be impeded because it will be on the up side, the smooth side, no welds.

All good fun though GM.

Do agree about the weight factor, probably an over kill with the welding, but water/material flow won't be impeded because it will be on the up side, the smooth side, no welds.

All good fun though GM.

Re: got know idea what I am doing!

Re: got know idea what I am doing!

hugh62 wrote:

Mmmmm ,well i'll give you 10/10 for the welding , ( nice welding bench too ) But yeah I think your wasting your time ,it won't work any near as effectively as a moulded plastic one , ( 1) those beads of weld are only going to impede the water / material flow ( 2 ) the rust factor ( 3 ) the weight factor after finishing it ,( wouldn't like to be carrying it any distance ) ( 4 ) the difficulty of mounting a magnet on it ( trying to extract any magnetic material )

I've only used one 2-3 times ? ? , ( used a mates one , under his supervision ) and he was preety pendantic in it's use ,and mostly uses it for concentrates , ( with some other material mixed in ) he stressed in the setting up of it ,ie ; the angle of it and the water flow of it ,were most important ,plus he used to use detergent in his recirculate water in order to soften the water up a bit , also allowing the plastic surface to become as smooth / shiny / slippery so as to allow water / material flow .Spiral Wheels are great bits of gear ,slow admittedly ,but great for concentrates ,and trying to extract magnetic black sands ,but only when used properly .Others might disagree ,but any way that's my opinion .

I am the first to admit I don"t know what I am doing, but when all fails blame the wife! Will the weld interfere when they are all on the up side of the spiral? As for rust I don't anticipate that being a real problem, today I painted the disc spiral with umpteen coats of epoxy industrial two pack paint. I don't anticipate carrying it around in my back pocket as the wheel is 900mm in diameter. Today I did make a fair amount of progress with the project so it should not belong before I can try it out. I will post some more pics later.

god's money- Contributor

- Number of posts : 52

Registration date : 2019-08-13

Re: got know idea what I am doing!

Re: got know idea what I am doing!

When you have it spinning GM, a starting point for the angle of the spiral is 21°.

As Hugh mentioned, recycle the water with an additive to stop gold flotation, Rinse Aid works a treat.

As Hugh mentioned, recycle the water with an additive to stop gold flotation, Rinse Aid works a treat.

Re: got know idea what I am doing!

Re: got know idea what I am doing!

It looks good to me. It's always fun working on a project. Look forward to any updates. cheers Pete.

piston broke- Contributor Plus

- Number of posts : 1633

Age : 65

Registration date : 2011-05-07

Re: got know idea what I am doing!

Re: got know idea what I am doing!

GM, Can not see on your photo, you do have a hole to allow gold to drop into your jar hanging on back of spiral when it reaches the end of its journey?

Re: got know idea what I am doing!

Re: got know idea what I am doing!

sure do, I will post some more pics tomorrow showing a bit more detail.Nightjar wrote:GM, Can not see on your photo, you do have a hole to allow gold to drop into your jar hanging on back of spiral when it reaches the end of its journey?

god's money- Contributor

- Number of posts : 52

Registration date : 2019-08-13

Re: got know idea what I am doing!

Re: got know idea what I am doing!

Last edited by god's money on Sun Aug 25, 2019 6:34 pm; edited 1 time in total

god's money- Contributor

- Number of posts : 52

Registration date : 2019-08-13

god's money- Contributor

- Number of posts : 52

Registration date : 2019-08-13

Re: got know idea what I am doing!

Re: got know idea what I am doing!

GM, You do know what you are doing and you have the gear in your shed to make it happen. This is going to be a very interesting project right through to when we see some gold in the jar.

**Very envious looking at lathe in the back ground** Did my time as a fitter & turner and my little lovely lady was going to buy me a lathe when I retired. Have had second thoughts through the years about telling her to save her money.

was going to buy me a lathe when I retired. Have had second thoughts through the years about telling her to save her money.

Looking forward to the next chapter.....

**Very envious looking at lathe in the back ground** Did my time as a fitter & turner and my little lovely lady

Looking forward to the next chapter.....

Re: got know idea what I am doing!

Re: got know idea what I am doing!

Nightjar, when I said I got no idea what i am doing I was really referring to retrieving gold, but when it comes to mechanical stuff I am not that much better considering its been a life long passion building things. I am sure you would cringe if you saw my self taught unorthodox methods! I have to admit it did take some arm twisting of the CFO to release some cash from the retirement fund to buy that lathe. Don't be envious I went bloody years with not much more than a stick welder and an angle grinder.Nightjar wrote:GM, You do know what you are doing and you have the gear in your shed to make it happen. This is going to be a very interesting project right through to when we see some gold in the jar.

**Very envious looking at lathe in the back ground** Did my time as a fitter & turner and my little lovely ladywas going to buy me a lathe when I retired. Have had second thoughts through the years about telling her to save her money.

Looking forward to the next chapter.....

god's money- Contributor

- Number of posts : 52

Registration date : 2019-08-13

Re: got know idea what I am doing!

Re: got know idea what I am doing!

Yeah looking good , your certainly putting some effort into it , love the pulley and yeah that's a lovely lathe

hugh62- Contributor Plus

- Number of posts : 363

Age : 62

Registration date : 2014-02-09

Re: got know idea what I am doing!

Re: got know idea what I am doing!

Got a bit done today, got a few leaks in the trough,but nothing a little peening and paint won't fix. I think the sissor lift will work just fine. Any suggestion on how I should place a bilge pump in the trough? and do I need a outlet drain? As I have said before I have no idea what I am doing!

god's money- Contributor

- Number of posts : 52

Registration date : 2019-08-13

Re: got know idea what I am doing!

Re: got know idea what I am doing!

GM, Your project is progressing very well.

A 12V bilge pump is all you need.

Spray bar on the wheel.

Water overflows from your trough into another Plastic toy box (Bunnings) Connect this box with a overflow (PVC) to a second box.

Place your 12V pump in this one (less fines/ leaf matter) to pump to your wheel spray bar.

And the needle returns to the start of the song.

And the needle returns to the start of the song.  and the water keeps recycling and the GOLD moves up the spiral into your gold jar.

and the water keeps recycling and the GOLD moves up the spiral into your gold jar.

Use little snips of lead from a sinker to test efficiency.

Will try and find photos.............

A 12V bilge pump is all you need.

Spray bar on the wheel.

Water overflows from your trough into another Plastic toy box (Bunnings) Connect this box with a overflow (PVC) to a second box.

Place your 12V pump in this one (less fines/ leaf matter) to pump to your wheel spray bar.

And the needle returns to the start of the song.

And the needle returns to the start of the song.  and the water keeps recycling and the GOLD moves up the spiral into your gold jar.

and the water keeps recycling and the GOLD moves up the spiral into your gold jar.Use little snips of lead from a sinker to test efficiency.

Will try and find photos.............

god's money- Contributor

- Number of posts : 52

Registration date : 2019-08-13

Re: got know idea what I am doing!

Re: got know idea what I am doing!

Watching your video ,I thought your bowl might of been a bit too close to your wheel ,and for cleaning out acsess , and I wouldn't go any smaller than a 1'' outlet ,and yeah I agree with Nightjar on the toy box's .

hugh62- Contributor Plus

- Number of posts : 363

Age : 62

Registration date : 2014-02-09

Re: got know idea what I am doing!

Re: got know idea what I am doing!

hugh62 wrote:Watching your video ,I thought your bowl might of been a bit too close to your wheel ,and for cleaning out acsess , and I wouldn't go any smaller than a 1'' outlet ,and yeah I agree with Nightjar on the toy box's .

hugh, the bowl sits on a scissor stand, so it can be moved up and down.

nightjar, thank for that, I had been racking my brains what the white PVC chute was about, now I understand!

What is the ideal RPM for the disc?

god's money- Contributor

- Number of posts : 52

Registration date : 2019-08-13

A little bit of Western Australia

A little bit of Western Australia

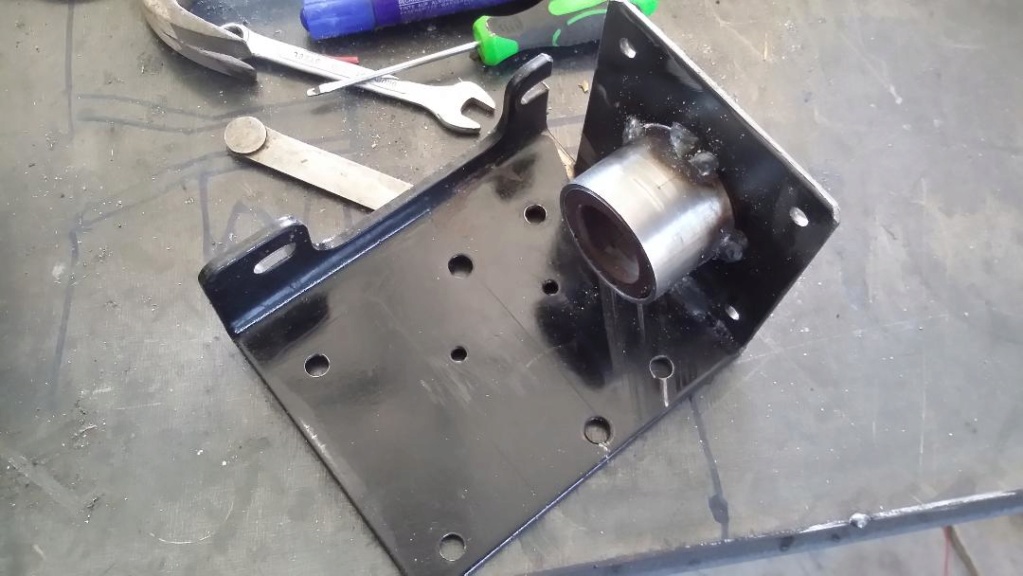

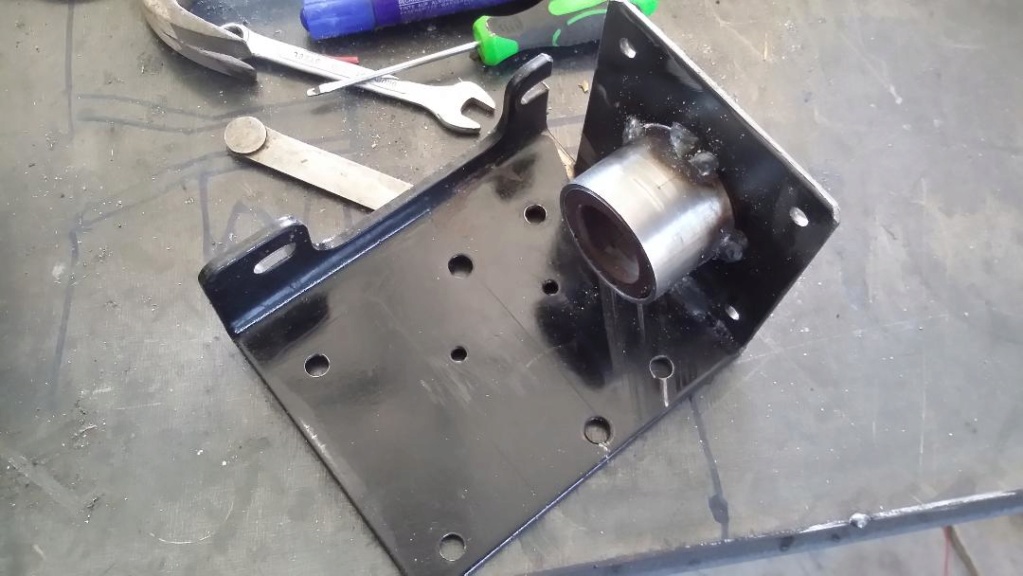

I ran into a snag, the wiper motor is too gutless to run the wheel! so I have gone down the path of an ATV winch motor. But that is not that easy either, one big experiment. I wish I had taken pic from the start but I was a little lazy but here are some.

Ha, So the little bit of WA is the jarrah bushes

Ha, So the little bit of WA is the jarrah bushes

Last edited by god's money on Sat Aug 31, 2019 1:22 pm; edited 1 time in total

god's money- Contributor

- Number of posts : 52

Registration date : 2019-08-13

god's money- Contributor

- Number of posts : 52

Registration date : 2019-08-13

Re: got know idea what I am doing!

Re: got know idea what I am doing!

GM,

A little mystified why a wiper motor doesn't run your wheel? Maybe to much power is wasted driving the "V" belt?

My wheel was driven with layers of rubber disc (conveyor belt) fitted directly to wiper motor shaft then mounted on the back of the wheel. (First photograph)

Speed is not essential, it is the amount of water flowing over the spirals. Too little and black sands end up in your jar, too much and the fine gold does not make it way up spiral.

BTW: Black Butt, grows around Kalgoorlie region is ideal for bushes, you can almost weld it. ***Back in the 60's/70's a Geraldton cray fisherman experimented with black butt bushes on his pot tipper. During my apprenticeship overhauled countless pot tippers renewing the traditional greased ball /roller bearings that had failed in the salty conditions. Not sure how long this method was used until the plastics came along.***

A little mystified why a wiper motor doesn't run your wheel? Maybe to much power is wasted driving the "V" belt?

My wheel was driven with layers of rubber disc (conveyor belt) fitted directly to wiper motor shaft then mounted on the back of the wheel. (First photograph)

Speed is not essential, it is the amount of water flowing over the spirals. Too little and black sands end up in your jar, too much and the fine gold does not make it way up spiral.

BTW: Black Butt, grows around Kalgoorlie region is ideal for bushes, you can almost weld it. ***Back in the 60's/70's a Geraldton cray fisherman experimented with black butt bushes on his pot tipper. During my apprenticeship overhauled countless pot tippers renewing the traditional greased ball /roller bearings that had failed in the salty conditions. Not sure how long this method was used until the plastics came along.***

Re: got know idea what I am doing!

Re: got know idea what I am doing!

Nightjar, the wiper motor would turn it on the low speed but not the second speed, i had the gearing giving me about 12 rpm on the wheel and when I changed pulleys to get more speed it would really struggle. I have read that some of the proprietary plastic wheels run between 22 and 15 rpm. Anyway, I have wondered for years about how you could mount a pulley on an ATV winch and now I think I know. I did see you had a rubber drive wheel on the wiper motor direct to the wheel but it worried me about getting traction if it got wet.

god's money- Contributor

- Number of posts : 52

Registration date : 2019-08-13

Re: got know idea what I am doing!

Re: got know idea what I am doing!

No way 22 rpm, your 12 rpm would be perfect.

The conveyor belt drive never gave me a problem even if it got wet, the cotton plies kept it stuck to the road like Coopers.

What amperage does your ATV winch draw? You may have to top up your battery every hour or two/

The conveyor belt drive never gave me a problem even if it got wet, the cotton plies kept it stuck to the road like Coopers.

What amperage does your ATV winch draw? You may have to top up your battery every hour or two/

Re: got know idea what I am doing!

Re: got know idea what I am doing!

I don't know what amp it will draw but with a small load (almost zero) I would guess somewhere around 15amps, but it could be much higher.Nightjar wrote:No way 22 rpm, your 12 rpm would be perfect.

The conveyor belt drive never gave me a problem even if it got wet, the cotton plies kept it stuck to the road like Coopers.

What amperage does your ATV winch draw? You may have to top up your battery every hour or two/

If the winch draws to much power I will go back to the wiper motor with a rubber, Coopers grip.

the wheel on the one you made what diameter is it. my wheel is 900mm and is as heavy as, at a guess goes 40 kgs.

do you know what vehicle you motor come out of?

god's money- Contributor

- Number of posts : 52

Registration date : 2019-08-13

Re: got know idea what I am doing!

Re: got know idea what I am doing!

Checked out the amps draw on the ATV winch, with no load 9.5 amps, a good fist grab on the shaft and I managed to get it to 10 amp. Also, blows a 5 amp fuse but not a 7.5 amp! this indicates to me I should get 4 to 6 hrs operation time

god's money- Contributor

- Number of posts : 52

Registration date : 2019-08-13

Re: got know idea what I am doing!

Re: got know idea what I am doing!

Looks like your ATV will do the job. A fly landing on top of the wheel will be enough to rotate it so you should be n business.

My wheel was same diameter as yours but it was made from aluminium and the spiral was 12mm square rubber glued to face, so a heap lighter.

Good luck with the drive, then you can work on the sprays.

My wheel was same diameter as yours but it was made from aluminium and the spiral was 12mm square rubber glued to face, so a heap lighter.

Good luck with the drive, then you can work on the sprays.

Re: got know idea what I am doing!

Re: got know idea what I am doing!

You're on a winner GM, as you say you retrieved all the lead so the gold will be there.

Your final set up looks great, congrats on a first class job.

Your final set up looks great, congrats on a first class job.

Page 1 of 2 • 1, 2

Similar topics

Similar topics» Water storage containers

» Business opportunity, Qld Property

» An idea for Minelab to consider - Cables

» idea for the 6000

» Crown Land vs Private Land

» Business opportunity, Qld Property

» An idea for Minelab to consider - Cables

» idea for the 6000

» Crown Land vs Private Land

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum